We design materials with theories, computations and data.

|

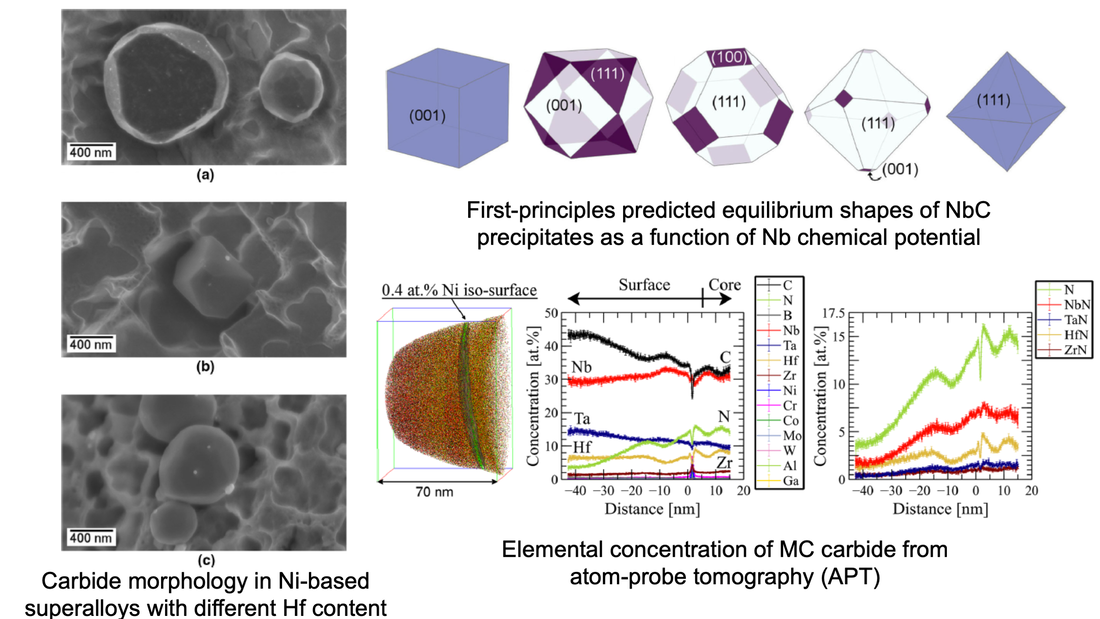

Carbide precipitates in Ni-based superalloys are often desirable phases that can improve high-temperature properties as well as aid in microstructural refinement of the material; however, they can also serve as crack initiation sites during fatigue. To date, the knowledge on carbide formation has mostly originated from assessments of cast and wrought Ni-based superalloys. As powder-processed Ni-based superalloys are becoming increasingly widespread, understanding the different mechanisms by which they form becomes increasingly important. In the present work, we performed detailed characterization of MC carbides present in two experimental high Nb-content powder-processed Ni-based superalloys and revealed that Hf additions affect the resultant carbide morphologies. This morphology difference was attributed to a higher magnitude of elastic strain energy along the interface associated with Hf being soluble in the MC carbide lattice. The characterization results of the segregation behavior of Hf in the MC carbides and the subsequent influence on their morphology were compared to density functional theory calculations and found to be in good agreement, suggesting that computational modeling can successfully be used to predict carbide features.

"MC carbide characterization in high refractory content powder-processed Ni-based superalloys", Metallurgical and Materials Transactions A, 49, 2340-2351 (2018) [PDF]

1 Comment

|

Categories

All

Archives

September 2020

|

RSS Feed

RSS Feed